How Source Factories Cut Supply Chain Costs for US Cannabis Businesses—Without Sacrificing Quality

The US cannabis industry is evolving at breakneck speed. As legalization expands across states, new brands, processors, and cultivators enter the market—driving unprecedented competition. For cannabis businesses of all sizes—from craft processors to multi-state operators (MSOs)—profit margins are under pressure. Rising costs of cultivation, extraction, regulatory compliance, and marketing leave little room for inefficiency. In this landscape, supply chain optimization has emerged as a make-or-break factor—and partnering with a direct source factory for cannabis vape hardware is one of the most impactful ways to reduce costs while maintaining quality.

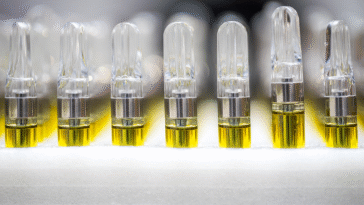

The Hidden Cost of Indirect Sourcing in Cannabis Vape Hardware

Many US cannabis businesses rely on distributors, agents, or third-party resellers for their vape hardware—and they’re paying a steep price for the middleman. Every layer between the factory and your business adds markup: distributors typically add 15-30% to the factory price, and resellers may tack on an additional 10-20%. For a cannabis brand ordering many vape products, that could translate to tens of thousands of dollars in unnecessary expenses annually.

But the costs go beyond price tags. Indirect sourcing often means:

- Longer lead times (distributors may not hold inventory for niche cannabis-specific hardware, leading to stockouts during harvest seasons);

- Limited customization (resellers offer pre-packaged options, not tailored to cannabis brands specific needs);

- Compliance risks (middlemen may not fully understand state-specific cannabis regulations, leading to hardware that fails child-resistance or material safety checks).

In a market where every dollar and every compliance misstep matters, these hidden costs can erode competitive edge.

Why Source Factories Deliver Unmatched Cost Efficiency for Cannabis Businesses

Direct partnerships with cannabis vape hardware source factories eliminate these pain points—delivering cost savings that go beyond just lower prices. Here’s how:

1. Factory-Direct Pricing: Cut Out Markup, Preserve Margins

Source factories manufacture cannabis vape hardware in-house, so there are no middlemen to add layers of cost. This direct relationship typically results in 20-30% lower pricing compared to indirect sourcing—without compromising on quality. For cannabis startups scaling their product lines or established MSOs managing high-volume orders, this translates to significant bottom-line savings. These funds can be reinvested into core operations: upgrading extraction equipment, expanding cultivation, or enhancing marketing to stand out in a crowded market.

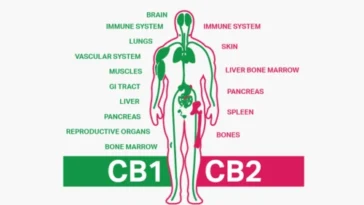

2. Compliance & Quality: Avoid Costly Rejections and Recalls

The US cannabis industry’s regulatory landscape is fragmented—each state has its own rules for hardware safety, child-resistant features, and material standards (e.g., California’s METRC tracking, Colorado’s product safety mandates). A reputable source factory specializes in cannabis-specific hardware, with production processes designed to meet these strict requirements.

3. Flexible MOQs: Optimize Inventory, Reduce Waste

Cannabis businesses face unique inventory challenges: extract shelf lives, seasonal harvest cycles, and unpredictable market demand. Unfortunately, most industry suppliers enforce rigid, high minimum order quantities (MOQs)—typically 5,000pcs or more—forcing businesses to overstock, tie up capital, or forgo testing new products due to prohibitive volume requirements.

VIQ stands out by offering far more flexible MOQs tailored to the cannabis industry’s needs: starting at just 3,000pcs or even less. This flexibility eliminates the burden of overstocking and tied-up capital, delivering cost-saving benefits that rigid suppliers simply can’t match.

4. Customization & R&D: Long-Term Cost Optimization

Cannabis extracts vary widely—from thin distillates to thick live resins—and one-size-fits-all hardware often leads to inefficiencies: leaks, uneven vaporization, or wasted product. Source factories with in-house R&D teams design hardware specifically for cannabis extracts.

This customization isn’t just about quality—it’s about long-term cost savings. Hardware tailored to your extracts reduces waste, improves consumer satisfaction (lowering return rates), and eliminates the need to adapt your extracts to ill-fitting hardware. For businesses looking to launch proprietary products, source factories also offer ODM (Original Design Manufacturing) services—turning custom concepts into market-ready hardware without the high costs of building an in-house design team.

The Bottom Line: Source Factories Are a Strategic Cost-Saving Partner

In today’s competitive US cannabis market, cost control doesn’t mean cutting corners—it means investing in partnerships that deliver efficiency, quality, and compliance. Source factories for cannabis vape hardware check all these boxes: they reduce direct costs by eliminating middlemen, avoid hidden expenses from non-compliance and waste, and provide flexible, customized solutions that grow with your business.

For cannabis brands, processors, and cultivators looking to protect margins and gain a competitive edge, the choice is clear: direct partnerships with source factories aren’t just a cost-saving measure—they’re a strategic investment in long-term success.

When evaluating potential partners, prioritize factories that specialize in cannabis-specific hardware, offer flexible MOQs (starting at 3,000pcs vs. industry-standard 5,000pcs), and have a track record of regulatory compliance. These qualities ensure you’re not just saving money—you’re building a supply chain that’s reliable, adaptable, and aligned with the unique needs of the US cannabis industry.