Introduction

The cannabis vaping market continues to mature as consumer expectations evolve from basic usability to advanced performance, safety, and reliability. Modern vape hardware blends engineering, materials science, and user-focused design, creating devices that deliver consistent vaporization without combustion. As vaping becomes a preferred consumption method for many users, understanding the internal mechanics of vape hardware has become increasingly important.

What Cannabis Vape Hardware Is Made Of

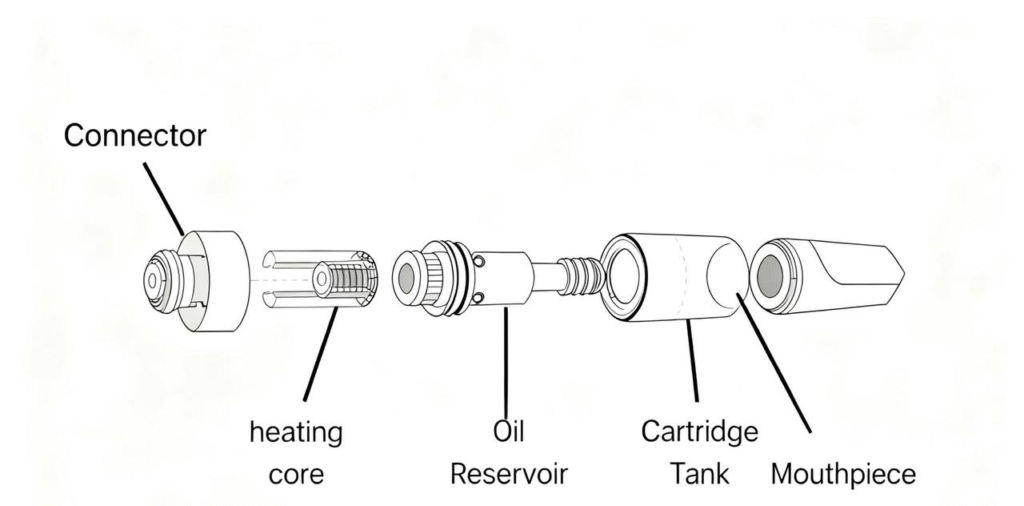

A typical cannabis vaporizer consists of four major components:

• Battery System

The battery provides the necessary power to heat cannabis oil to vaporization temperatures. Modern devices feature lithium-ion cells-supported by smart power modulation and short-circuit protection circuits to ensure consistent output and user safety.

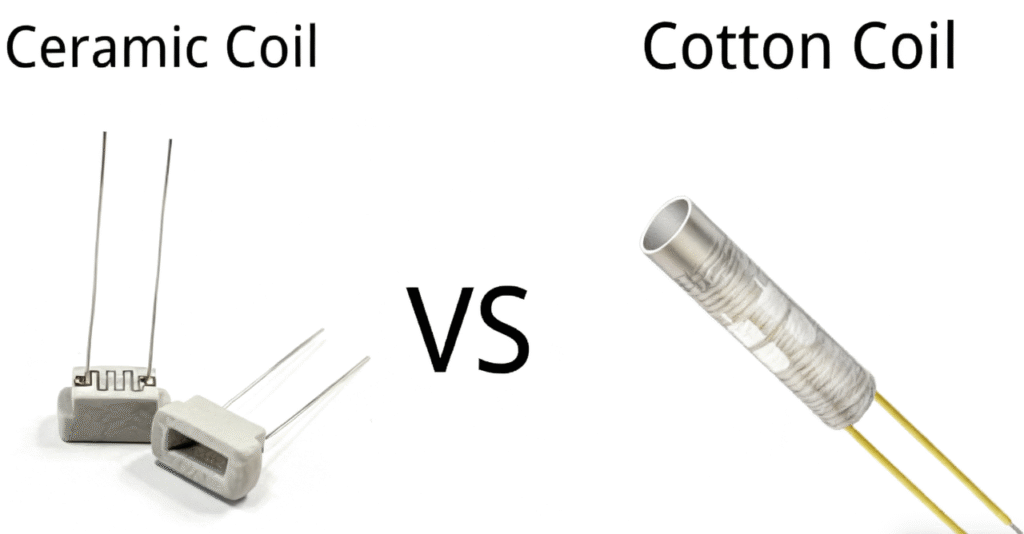

• Atomizer / Heating Core

The heating element is responsible for converting electricity into precise thermal energy. Ceramic heating cores have become the industry standard due to their stability, even heat distribution, and ability to preserve terpene flavors.

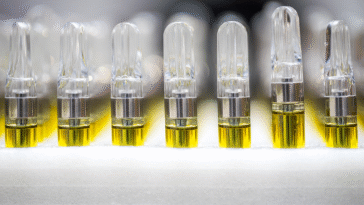

• Oil Reservoir / Cartridge Tank

This chamber stores cannabis extract. Advances in tank materials—such as medical-grade stainless steel, borosilicate glass, and polymer solutions engineered for high-temperature use—have significantly improved leak resistance and oil compatibility.

• Mouthpiece Structure

The mouthpiece guides vapor flow and contributes to the overall airflow experience. Ergonomic shapes, optimized airflow channels, and food-grade materials now form the baseline expectations of discerning consumers.

Engineering Innovations Driving the Industry

Recent years have seen rapid advancements across all levels of vape hardware:

• Clog-Resistant Pathways

Improved airflow geometry prevents blockages caused by oil viscosity changes under varying environmental temperatures.

• Dual-Airflow Intake Systems

Enhanced airflow contributes to smoother vapor production and more consistent inhalation resistance.

• Chip-Regulated Power Systems

Built-in microchips govern temperature stability, protecting against overheating and improving device safety.

• Material Upgrades

The move toward medical-grade materials ensures lower heavy-metal migration risk and higher compliance with regulatory testing.

Why Consumers Care About Hardware Quality

Consumers increasingly expect:

- Consistent vapor quality

- Reliable heating without burning

- Improved flavor retention

- Longer cartridge life

- Verified safety and compliance

- Stronger leak-proof design

Hardware now plays a central role in brand trust. Manufacturers who invest in engineering refinement and transparent quality assurance are better positioned as the market continues to expand.

Conclusion

As cannabis vaping becomes more mainstream, hardware innovation remains one of the most influential forces shaping user experience. From heating cores to chip-based power control, the industry continues to move toward safer, smarter, and more efficient solutions—setting new expectations for performance and reliability.